Key areas where data analytics delivers business value in logistics

-

Cost reduction and operational efficiency

Data analytics transforms logistics through the integration of real-time insights and predictive intelligence. This allows companies to find the best shipping routes, reduce delays, and enhance warehouse operations—thereby decreasing costs while maximizing operational efficiency and resource utilization. What insights can be gained?

-

Optimizing transportation routes

By analyzing data from sensors in vehicles, traffic patterns, weather data, and past delivery performance, advanced analytics systems can recommend the most effective routes for trucks. Route optimization contributes to lower total logistics costs, better fleet utilization, and less fuel usage.

-

Minimizing delays and idle time

Cutting down on idle time increases fleet efficiency, minimizes fuel waste, and guarantees on-time delivery. AI-based scheduling, real-time tracking, and predictive analytics help optimize delivery routes and prevent traffic jams.

A good real-world example is Amazon, which employs advanced data analytics to forecast delivery delays and dynamically adjust routes. In many areas, this allows Amazon Prime to uphold its promise of one-day or same-day delivery.

-

Lowering warehouse costs

Demand forecasting powered by AI anticipates patterns in product demand, enabling warehouses to effectively modify inventory levels. Efficient inventory management lowers storage costs and avoids overstocking.

For example, Walmart, a prominent retailer, effectively uses generative AI to increase demand forecast accuracy, resulting in a significant reduction in excess inventory and stockouts. By leveraging GenAI-powered solutions, they managed to boost operational efficiency and customer satisfaction.

-

Optimizing transportation routes

-

Improved supply chain visibility and resilience

Despite logistics companies’ commitment to improve supply chain visibility, only 6% of organizations have achieved this goal. A lack of resilience remains a problem, too. According to BCI’s 2024 survey, 80% of companies experienced supply chain disruptions last year, with 43.6% of the respondents attributing problems to third parties. Here’s how modern data analytics solutions help build more transparent and resilient supply chains.

-

Real-time tracking of shipments

GPS tracking devices with IoT capabilities offer real-time information on the location and status of shipments. Improved visibility into cargo locations helps reduce delays and improves ETA (estimated time of arrival).

An example from our portfolio shows how a global logistics company revolutionized supply chain management with an AI-driven, end-to-end IoT logistics platform that seamlessly connects shippers, brokers, and carriers. The challenge was to provide an easy, collaborative solution that streamlines complicated multi-operational logistics operations, such as shipment tracking and automated paperwork. By implementing machine learning-powered decision support, real-time GPS tracking, and automated workflows, the platform now serves 25,000 active users, including major enterprises like DHL, Maersk, and Ryder. This has significantly reduced costs, paperwork, and delivery inefficiencies while improving supply chain visibility and decision-making.

-

Risk mitigation through predictive analytics

The logistics sector is riddled with risks, ranging from weather delays to geopolitical concerns. Early identification of possible bottlenecks and disruptions enables companies to proactively respond to any anomalies and swiftly develop mitigation strategies.

For example, Walmart uses predictive analytics tools to mitigate supply chain disruptions caused by natural disasters. When hurricanes and storms are predicted, Walmart’s predictive models assess customer buying patterns and logistical limitations to pre-stock essential goods in at-risk areas.

-

Scenario modeling to prepare for supply chain disruptions

Businesses that prioritized supply chain resilience experienced an average revenue growth of 23% between 2018 and 2023, outperforming their peers, who saw a 15% increase. Companies can create reaction plans by simulating various disruption situations, such as natural catastrophes or geopolitical conflicts, using scenario modeling. Anticipating different disruption scenarios helps maintain business continuity.

For example, Jabil, a global manufacturing company, has provided its suppliers with proprietary tools to evaluate risks, including new platforms that enable them to upload data for predicting potential disruptions.

-

Real-time tracking of shipments

-

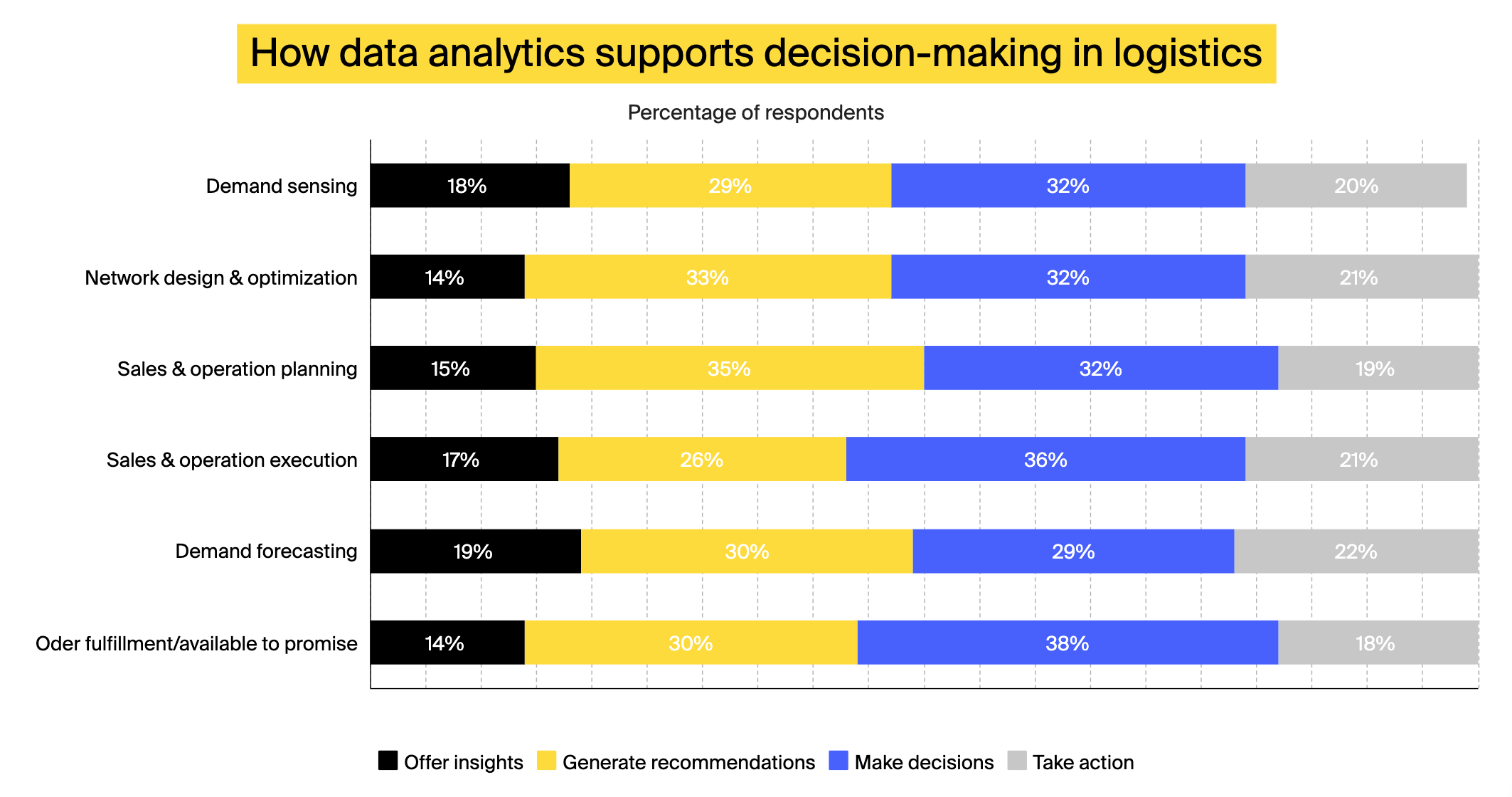

Enhanced decision-making with AI

Data analytics in logistics and supply chain is playing an increasingly vital role in enhancing decision-making and ensuring greater accuracy in planning. For example, according to Gartner, 38% of the supply chain leaders surveyed use data analytics solutions to support decision-making in order fulfillment processes.

Businesses can make smarter, data-driven decisions that enhance performance and help gain a competitive edge by using AI-powered data analytics. Here are some key areas where AI is changing operational success and decision-making.

-

-

Data-driven demand forecasting

AI algorithms use market trends, past sales data, and external factors to forecast future demand, which minimizes the danger of overstocking or stockouts while optimizing inventory levels.

A notable example is Nike, which uses AI-driven demand forecasting to guarantee the best possible product availability throughout their supply chain. This helps lower inventory holding costs by 20% while enhancing product availability.

-

Predicting equipment failures with IoT and AI

By combining IoT sensors with machine learning models, companies can monitor fleet and warehouse equipment health, predicting failures before they occur. Anticipating equipment breakdowns lowers maintenance expenses and unplanned downtime.

-

AI-powered logistics simulations to optimize supply chain strategies

AI-driven digital twins simulate various logistics scenarios to uncover the most efficient strategies, enabling businesses to optimize supply chain operations and enhance overall efficiency.

A good example is a project in Singapore aimed at leveraging digital twin technology to optimize logistics infrastructure, specifically at the country’s new container shipping megahub. Spearheaded by the Singapore Port Authority in partnership with the National University of Singapore, the initiative focuses on integrating real-time data, AI-driven predictive capabilities, and simulation models to improve efficiency. A digital replica of the port allows stakeholders to improve layouts, resource allocation, and operations, including vessel berthing and cargo processing.

-

Data-driven demand forecasting

-

Revenue growth and customer satisfaction

According to Gartner, over 83% of firms are increasingly understanding the vital role of the supply chain in improving the customer experience and are incorporating it in their digital business strategies. By improving delivery speed, minimizing stockouts, and customizing shipping options, data analytics is transforming logistics for businesses and consumers alike.

-

Faster, more reliable deliveries leading to improved customer experience

Data analytics for logistics is assisting organizations in meeting and surpassing consumer expectations, and customer satisfaction is a crucial factor for logistics firms. By ensuring quicker, more dependable delivery and giving customers precise information about their orders, businesses are able to improve the whole customer experience.

-

Personalized logistics solutions

AI-powered personalization customizes shipping choices, providing dynamic pricing and delivery preferences tailored to each individual client. This significantly improves the customer experience and creates new business opportunities.

For example, DHL Express employs AI to assess client shipping habits and recommend tailored delivery choices, hence enhancing customer satisfaction.

-

Reducing lost sales due to stockouts by improving inventory predictions

Retailers and warehouses may forecast demand and make real-time inventory adjustments with the use of predictive analytics. Minimizing stockouts guarantees that consumers will always find the items they require.

-

Faster, more reliable deliveries leading to improved customer experience

Measuring the ROI of data analytics in logistics

In recent years, there has been a surge in the adoption rate of data analytics in supply chain management and logistics. According to the 2022 survey from Gartner, however, only 8% of logistics and transportation leaders have a clear understanding of external and internal supply chain conditions, which highlights inefficiencies in their approaches to data analysis. Furthermore, 42% of the surveyed highlighted misalignment between priorities and reality as the main obstacle to making sound business decisions. These problems can be largely attributed to the lack of a structured approach to performance measurement and failures to match data analytics implementation goals to business outcomes.

Accurately assessing both hard and soft ROI is impossible without clearly defined outcomes and predefined key performance indicators. Taking a more structured approach and establishing clear KPIs that align with business objectives is essential for effectively assessing the value of data analytics in logistics.

KPIs to track the value of data analytics

| Metrics | What to monitor | KPIs to track |

|---|---|---|

|

Cost-saving metrics |

Fuel consumption, operational efficiency, labor costs |

Total Fuel Consumption, Inventory Turnover Ratio (ITR), cost of carry, Labor Cost per Order |

|

Efficiency metrics |

Delivery performance, warehouse throughput |

Average Delivery Time, Perfect Order Rate, Picking Accuracy Rate, Inventory Turnover Rate |

|

Risk management metrics |

Supply chain disruptions, predictive maintenance |

Transportation Disruption Rate, Number of Supplier Failures, Mean Time Between Failures, Unplanned Downtime Percentage |

|

Customer experience metrics |

Order fulfillment, return rates |

Order Processing Time, On-Time Delivery Rate, Return Reason Categorization, Order Accuracy Rate |

How to set up a data-driven ROI measurement framework

Businesses require a structured framework that explicitly aligns analytics initiatives with strategic business goals in order to effectively gauge the return on investment of data analytics in logistics. This helps ensure that data insights translate into quantifiable improvements throughout logistics operations.

-

Aligning data analytics goals with business objectives

For maximum impact, data analytics activities should tackle fundamental logistics issues and be in line with larger business goals. To maximize returns on data analytics investments, your company should establish clear, measurable goals such as:

-

Increasing delivery accuracy and reducing delays

-

Cutting operational expenses through route optimization

-

Improving warehouse efficiency by minimizing stock discrepancies

-

-

Continuous monitoring and benchmarking against industry standards

Before launching analytics initiatives, identify and document key performance indicators from the table in the previous section, such as on-time delivery rate, inventory turnover, and transportation costs. Continuously monitor and refine analytics models based on real-time and historical data insights.

Next, compare internal performance to industry standards to evaluate competitiveness, identify gaps, and implement best practices. For example, if the industry standard for on-time delivery is 95% and your company is at 88%, predictive analytics can identify route inefficiencies and recommend improvements.

Overcoming common challenges in unlocking data analytics value

Logistics operations can greatly benefit from data analytics. However, to unlock maximum value from data analytics investments, companies need to overcome several challenges:

-

Data silos and lack of integration between technology systems

Data silos are one of the biggest obstacles to getting value out of data analytics. Data silos occur when various departments or systems store information separately, thus limiting seamless data flow and hampering real-time visibility. Data in logistics is frequently spread across a variety of platforms, such as enterprise resource planning (ERP) tools, transportation management systems (TMS), warehouse management systems (WMS), and Internet of Things (IoT) devices.

It’s critical that businesses provide system interoperability by utilizing advanced cloud-based solutions and API-driven integrations. A unified data ecosystem facilitates data access and analysis for all parties involved, from warehouse operators to supply chain managers, resulting in more informed and quick decisions.

-

Selecting the wrong technology stack

Many businesses make the mistake of either overly complicating their technological infrastructure or not coordinating it with their real business requirements. Companies might rush to adopt AI-driven solutions, for example, when simpler, RPA-based automation solutions and business intelligence (BI) dashboards could accomplish the same goals more quickly and cheaply. While gradual upgrades may be more effective, some would try to completely redesign legacy systems, which would come with significant expenses and operational disruptions.

Prior to investing in solutions, logistics companies should evaluate their needs and embrace technology strategically. It is necessary to avoid unnecessary complexity and make sure that new technologies are in line with long-term business objectives by performing a cost-benefit analysis and implementing scalable, modular solutions.

-

Inconsistent data quality

When it comes to analytics, the data being used is the most important thing. The use of data that is inconsistent, erroneous, or out of date can result in flawed insights, which in turn can lead to costly miscalculations in the execution of logistical operations. For instance, overstocking, stockouts, or ineffective route planning may result from inaccurate demand predictions brought on by low-quality data.

It is absolutely necessary to initiate the establishment of a solid data governance system. This includes the implementation of systems for validating data, conducting frequent audits, and establishing clear protocols for data entry. Companies could also use machine learning-powered data cleansing solutions to find and resolve anomalies, ensuring that data is reliable and usable.

-

Demonstrating long-term ROI beyond cost savings

Many companies find it difficult to gauge the complete return on investment from data analytics initiatives, frequently focusing just on cost-cutting measures like labor cost reductions, fuel savings, or warehouse efficiency. The true worth of data analytics in logistics, however, goes beyond cost reductions and encompasses strategic benefits like increased supply chain resilience, customer satisfaction, and decision-making speed.

Businesses need to create performance metrics that go beyond direct cost reductions in order to properly measure the true value of data analytics in logistics. This involves monitoring customer satisfaction metrics, including on-time delivery rates and decreased shipment delays. Furthermore, operational efficiency metrics, such as order fulfillment speed and route optimization success, offer insights into logistics performance. Finally, competitive differentiation indicators, like market share growth and the company’s ability to adjust to supply chain interruptions, aid in evaluating long-term strategic benefits.

On a final note

In the field of logistics, data analytics is more than simply an operational tool—it is also a strategic enabler that drives efficiency, agility, and competitive advantage. However, in order for businesses to truly capitalize on its potential, they need to move beyond basic implementation and focus on effectively assessing return on investment.

The next stages are very evident for logistics leaders who want to maximize the value of data-driven insights. These steps include investing in the appropriate analytics strategy, technology, and tools that are tailored to the needs of the business and partnering with data consultants to expedite digital transformation. By adopting a structured approach to data analytics, companies can improve their decision-making processes, strengthen the resilience of their supply chains, and maintain a competitive advantage in a logistics landscape that is becoming increasingly complicated.